What is Juice Concentrate and What Does it Do to My Cider?

Poverty Lane Orchards, producers of Farnum Hill Ciders. (Photo by Jeff Alworth)

The history of cider doesn’t involve much in the way of technical innovation until the 20th century. The biggest challenge for cidermakers has always been the juice—it is heavy and takes up huge amounts of space. Because apples ripen only once a year, cidermakers end up having to deal with a year’s supply as it becomes available between September and the end of the year. But in the 20th century, clever people figured a work-around: concentrate the juice, store it, and then rehydrate and ferment as needed throughout the year. And that’s what large producers do.

I had never really put a lot of thought into how juice is concentrated until I sat in on a session at CiderCon – an industry conference – with Terry Chambers, President and GM of FruitSmart, a company that prepares and sells apple juice and apple juice concentrate (AJC) in Yakima. FruitSmart is not principally a supplier to cider makers, but they have lately started getting requests, and Chambers was at CiderCon in Portland, Oregon to explain what the different products were and how they’re processed. It was enlightening.

When apples come to FruitSmart, the process for all products begins the same way: the fruit is inspected, washed, and milled or pulped. That’s exactly what you’d find in any traditional cidery. The product lines then diverge, going toward unprocessed juicing or processing. For the unprocessed products, the milled apples are then pressed and either pasteurized or sold unpasteurized. (The latter product is new and offered on the request of cideries.) It’s cloudy and viscous—the rustic sweet cider you’d buy at a farm stand.

The processed track looks a lot different. After milling, the pulp is heated to 190°F or higher. The juice is then treated with enzymes for 30 to 90 minutes, which breaks down those viscous compounds in regular juice. Then it goes through “hot extraction” (juicing), filtration, and then concentration, which is a process like distillation (more heat) where the water is boiled off. To recap: processed juice is heated three times and broken down with enzymes in its long journey toward concentration.

The effect is, as you would guess, profound. During the session we tasted the regular unprocessed juice, a processed juice that hadn’t been concentrated, and then juice made from concentrate. The unprocessed juice was farm-fresh, complex, aromatic, and viscous on the tongue; it also had that slightly chalky mouthfeel you get from apple skins. The processed juice is what you remember from childhood—very light color, perfectly clear, vaguely appley aroma and a one-note, very sweetly apple flavor. The concentrate had even less color—it was just this side of water—absolutely no aroma, was the consistency of water, and it didn’t even really taste of fruit at all. It was basically a sugar-water solution.

In fact, all the flavor and aroma gets blown off during the process of concentration, and FruitSmart captures it and sells it as “fruit essence.” If you are a juice-box maker, you might buy both the AJC and the essence and when you rehydrate before packaging, you’d spritz the dull juice with a bit of essence to make it taste like apples.

So what to make of all this? There is a very heated but mostly subterranean war going on between small cideries who make “orchard-based” products without concentrate and larger producers who have to rely on AJC to meet production demands. I had mostly been agnostic about the AJC debate: so long as the juice was rehydrated to its original strength, this seemed like a convenience rather than a transgression. But learning more about the concentration process has made me question that.

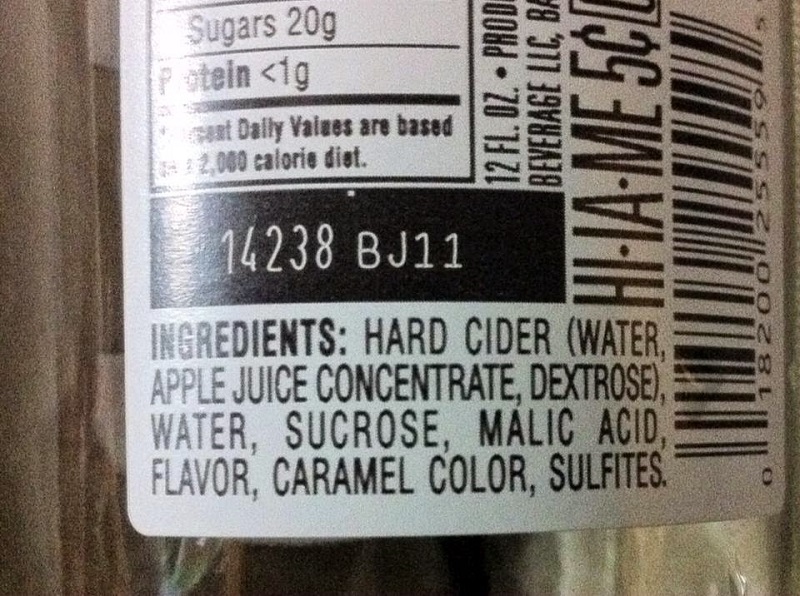

The label of a bottle of Stella Cidre. (Photo by Jeff Alworth)

If you pick up a bottle of supermarket cider, you’ll likely find a string of ingredients that includes words like water, sugar, apple juice concentrate, carbon dioxide, malic acid, natural flavor and caramel color. All of those extra ingredients are necessary to replace everything that got stripped out during processing: water and sugar to rebalance the concentrate, natural flavor (like FruitSmart’s essence) to replace lost flavor, and caramel color to restore its lost hues.

There’s nothing inherently wrong or immoral about using AJC in a cider. Many cideries only use a portion, blending in more flavorful whole juices to add character. And even when a cidery uses only AJC, they reconstruct the flavors and aromas to create a profile they’re looking for. It’s not even hugely “unnatural,” in the sense that these constructed ciders use natural (albeit processed) ingredients. Rather, the takeaway for me is realizing how processed AJC really is, and how manipulated ciders using it must by necessity be. It results in a consistent, mass market product that can be made year-round. If you’re looking for the flavor of an orchard in your cider, though, you won’t find it in products that use apple juice concentrate.

Real Cider is just fresh pressed over ripe ground ,etc. apples per type ,filtered treated via infra red-u v sterilization….,then allow natural fermentation for an couple weeks or more…I like the five day or so [sweet] hard cider depending the apples of choice…

You make it sound so easy.

Apples are rarely over ripe.

The juice is not filtered or treated in any way.

Fermentation can last as long as 9 months depending on climate.

If it’s Sweet it will have added sweetener.

One can stop fermentation at any time to preserve any degree of sweetness, vs alcohol.

Nonsense! You can only stop

By adding sulphite or pasturisation or nmicro filtering all of which rip

Out flavour and character – temperature drop can only delay fermentation

I halt the fermentation of young, partially fermented, semi-sweet cider by drinking it.

You can also hault fermentation by compression i.e. carbonation or by cooling/freezing to the point that the yeast die. Neither of these 2 ways give off flavors of a chemical nature.

Tim Beer,

You have no idea about apple cider!!

This goes way beyond “real cider”… where does infrared/uv sterilisation come into it? And if it’s only fermented for a couple of weeks it will be quite revolting!

Great to see you are waking up over the pond to what we Traditional cider makers in the UK have been arguing about for years, it’s time Joe public were educated as to what “real cider” is compared to the dubious practices employed by the big boys in our industry,added water should be stated on the label!

amen! Barry.

I believe that ‘Cider’ as a name should be restricted to products made solely from apples. If it’s made from AJC, water, dextrose, malic acid, sweetners, colourings – it’s no more a cider than Apple Tango is. whatever it is, it ain’t cider, which is fermented apple juice. 🙂

Thanks for a great post. I’m Sorry now that I missed this session. I knew that concentration would alter the flavor profile of the resulting liquid but hadn’t quite realized just how stripped it would be.

This is much like making cheese from dry casein rather than milk (pretty common in the US). AJC may not be “immoral” as long as ALL ingredients are stated on the label. Here in Poland with have the problem with the majors like Strongbow: long list, not a word about AJC. A revealing post, thank you

Big fan of natural apple cider. Grew up in RI where I have tasted some of the best apple cider. All this crap about boiling, reboiling just takes all the freshness out of the juice. I understand demand vs natural. Not good for ones body and difficult to digest. Be careful and do your research. Stick with organic if you can. Way too many chemicals. Jb

I’m in the process of moving from home brewing to ciders. I personally prefer cider to beer, and i enjoy the fact that ciders have as much variety as beer does, including the sweet fruity ciders I prefer. At the moment my cider making is focused on cider kits. To see what they are, how they work, and what the product is like. So far I’m pleased. It’s a good source for winter brewing. This summer I’ll make myself a large home press and start making various juices and cataloging my various accomplishments looking for desired recipes. I think this is going be a real fun learning curve.

To heat cider, either as sweet juice or hard cider is to ruin it. Quality ciders, like wines, are never heated.

Late response to James L. Wolcott: we make real cider without sterilization (unnecessary & bad for quality); without filtering before fermentation (ditto); with champagne yeast (reliable, flavorless). To Tim Beer: people growing apples for cider try to let them fully ripen; some even need to drop to reach their best. You’re right that dessert apples are picked and packed to withstand shipping and “snap” when bitten, so make less vivid cider when culls are used. Farnum Hill.

I don’t understand why the juice must be heated in order to concentrate it.

What prevents room temperature vacuum distillation from being used?

Similarly, why not reverse osmosis?

If sterilization/pasteurization is needed, why not use High Pressure Processing instead of heating?

You can filter cider or centrifuge it to stop fermentation without stripping flavor.

Hi in market fruits beer non alcoholic is sold do they use fruit concertante of Apple or not if it is made what is formulated of it

Dose in market fruits concertante beer is sold what is processed of making it

I was reading about a method of concentrating where you freezer your Apple juice then drip the juice out and discard the I’ve left behind, anyone ever try this?