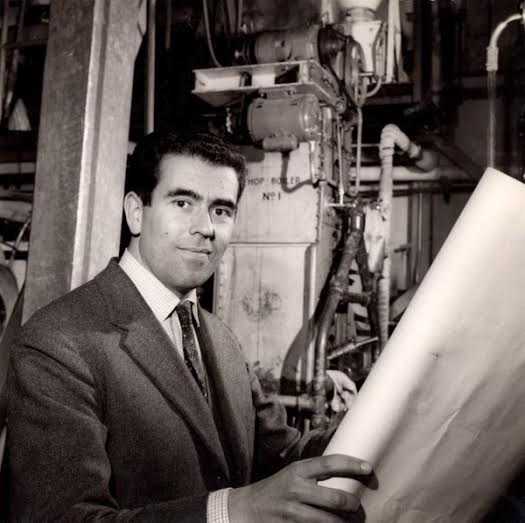

Michael Ash drinks a pint of Guinness. (Photo by Jeff Alworth)

[Full Disclosure. The following post came as a result of a visit I made to Dublin to the Guinness brewery. The folks at Diageo, Guinness’ parent company, paid for the trip and put me up while I was in Dublin. Guinness is also a sponsor of my personal blog, Beervana.]

If you walk into any decent pub or brewpub, you’ll almost certainly encounter one beer served “on nitro.” It has long been a standard system for stouts and some pale, creamy ales, but lately breweries have been pushing it out to other styles as well, notably (and unsurprisingly) IPAs. When used to “carbonate” beer, nitrogen creates a silky texture and produces a dense, mousse-like head. Unlike regular carbon dioxide bubbles, which continue to absorb more CO2 as they float to the surface and become larger and more buoyant, nitrogen doesn’t dissolve as well, and so the bubbles remain tiny. And those tiny bubbles are responsible for that creaminess.

(Photo courtesy Lucy Ash)

Although nitrogen is a natural gas—it’s a major constituent of the air we breathe—it does not appear naturally in beer, like carbon dioxide. It had to be invented rather than discovered. The man who did so was a mathematician named Michael Ash, who had been hired by Guinness in 1951. I had the very good fortune of meeting Mr. Ash a couple months ago when he was honored by Guinness for his contributions to the brewery. I was saddened to learn that he died on April 30, just six weeks later. His story has not been broadly shared, but it’s pretty remarkable—and not just because he invented nitro.

Ash was born in Calcutta in 1927, and went on to Trinity College, Cambridge, where he was awarded a “triple first” in his studies and was the top scholar at Cambridge. After graduation, he taught mathematics at Bedford College for three years before joining Guinness. He came in with a cohort of other smart people who didn’t have a background in brewing; this was part of a new initiative at Guinness to encourage innovation. Of course, Ash was the first hire they made.

Guinness brought me to Dublin to participate in an event honoring Mr. Ash. I was joined by London writer Pete Brown and local Dubliner John Duffy. When we sat down to interview Ash, he explained what it was like going to work for the brewery. “It was a semi-academic atmosphere, you see,” he said. “They brought in all these science graduates, they all came from the same universities, so in a way it was like an academic atmosphere itself. It was different, you’re quite right.” The new arrivals were sent to St. James Gate to learn each aspect of the brewing process. “To get trained, you had to do every manual job in the place. That took a year and a half. So this was at age 21; I had to get my hands dirty.”

Once he’d been trained as a brewer, he returned to the Park Royal Brewery in London. He was appointed head of the Sample Room, where he led a team of 20 charged with improving the shelf life of bottled Guinness. Ash himself was privately interested in a different challenge, however. Most Guinness outside Ireland was sold in the bottle, but the Irish drank it from a convoluted dispensing system. Figuring out how to streamline the process was a difficult enough conundrum (they called it the “draft problem”), that even after 20 years no one had solved it.

To give you a sense of what they were trying to replace, here’s how Martyn Cornell describes Irish Guinness in Amber, Gold, and Black:

“In the pub, the casks containing this highly conditioned beer were known as ‘high,’ while casks containing maturer, less lively beer were know as ‘low.’ Publicans would fill glasses three-quarters full from the ‘low cask’ and then top them up with foaming beer from the ‘high cask.’ The ‘high’ and ‘low’ cask system was in use until at least the 1960s.”

Ash recalled this himself. “The barman would take a whole minute to fill one glass. He had to get a low pressure cask over a period of time and then the high pressure one, and he had to mix them. He had to be very skilled, the Irish publican, because it took a minute to get a glass. Every barman had his own process. It was all very amusing.”

Hear Ash describe the process himself in this audio clip:

He worked on the riddle of how to replace this system for years. Very early on, he saw nitrogen as the solution. It was “such an obvious gas,” he said. “It’s completely inert and it’s three-quarters of what we breathe. It was perfect for this purpose.” The trick wasn’t selecting the right gas, though; it was designing a keg that would work with it. Inside Guinness, Ash’s quest was regarded as quixotic, and other brewers chided it as “daft Guinness” and the “Ash Can.”

Eventually, working with a keg designer, he did figure it out. He described it to us. “There were two parts. One part where we had to have a reducing valve, and one part for the two gases, nitrogen and CO2, high pressure, reducing valve, low pressure, flood the beer. When we drew off the beer, the gas would come through the reducing valve giving you a constant pressure.” The keg went through two designs before Guinness started sending it out to pubs, rushing at the end to get the project launched by 1959—the brewery’s 200th anniversary.

It’s safe to say that Ash’s invention revolutionized Guinness and Irish stout. It’s hard to imagine Irish stout served any other way, now (and not just Guinness), and so much of what nitro brings to the drinking experience has become fused with the brewery’s identity. The “surge,” that period of settling when the bubbles seem to flow down as the head settles, has been the subject of ad campaigns for decades. Pouring a perfect pint, topped with the precise depth of snowy head, is an activity the brewery treats almost like a sacrament.

And yet, it’s also true that nitrogen had a huge effect on the flavor and experience. Nitrogen scrubs flavor and aroma (or perhaps it’s safer to say nitro inhibits its expression) and a sizable number of drinkers hated it. Even today, it has a mixed reputation, and you hear grumbling about how nitro “ruined Guinness.” This is not surprising given that the old system was not just a way of dispensing a beer, but combining batches of different vintages. No doubt it did taste very different. There are, of course, millions of people who would vehemently argue the point. But whichever camp you inhabit, it’s hard to argue what a huge force it has been.

On an entirely separate note, it was fascinating to meet Mr. Ash. Although Guinness trained him as a brewer, he was unlike any brewer I’ve ever met. Brewers typically have a scientific bent, but they also have a personal connection to the liquid they bring to life. Ash had the mind of a pure scientist. A typical brewer would have described nitrogen in the context of the way the beer tasted, felt on the mouth, and facilitated pub-going. For Ash it was a solely intellectual riddle. Guinness fiddled at the margins with the “draft problem” from 1932 until Ash got there, and then he set about solving it the way a mathematician would solve any problem.

Show me a brewer and I’ll show you a romantic. But Ash, back at the brewery for the first time in decades, didn’t get a tear in his eye for the old days. Instead, talking about his starring role in this drama seemed to spark anew that curiosity for discovery. He was energized by talking about how he’d solved the problem.

The Guinness of that era was a very different company. Bringing in non-brewers precisely so they would arrive at new solutions to old problems was a radical move. It undermined conventional wisdom—and the people who were committed to the status quo. Guinness decided to follow Ash’s lead and allowed its product to become transformed by a new dispensing system. It was the kind of move modern, risk-averse corporations (like Diageo, Guinness’ parent company) don’t make—and perhaps rightly so. Fundamentally changing a product can destroy a company. Yet there was a time when they were willing to do it, and that posture changed the trajectory of one part of brewing.

In any case, the next time you have a pint of beer on nitro, raise it to Michael Ash. You wouldn’t be drinking it without him.

Jeff Alworth is the author of the book, The Beer Bible (Workman, 2015). Follow him on Twitter or find him at his blog, Beervana.

Thank you, Jeff, for telling this story of a man and the process he created, still significant to the beer world. It’s beer history many of wouldn’t have known.

What a phenomenal article to read drinking my knock off! This one’s not for Arthur, but for Ash…

All very good, but I wonder what he thought of the flavour difference between the two versions, not just the (possible) effect of nitrogen on hop character, but the taste of a product that was now filtered.

I imagine Guinness must have been concerned about taste, as something presented to Irish drinkers that was very different from what came before surely would have been remarked on by the market, possibly the subject of press accounts at the time, etc. Yet I have never heard that this occurred.

Presumably then the two versions were fairly close, or were they?

Same thing for pasteurization: was it applied right away when the new system came in, if not why, etc.?

Gary

I’m listening now to Michael Ash’s explanation in the recording. To summarize what he is saying, in Ireland, an “air tent” (?) – compressed air? – was used to dispense draught Guinness.

This did not acetify the beer since turnover was fast. But it still took a minute to pour a pint from 2 casks.

In England, slower turnover was resulting in sour beer due to the impact of oxygen over a longer period. That was the pressing problem for Guinness to address (which is fully understandable).

So, they eliminated oxygen to deal with both problems – CO2 and nitrogen only would be used to dispense the beer.

Nowhere does he speak of palate as a consideration, so I’d guess he thought any difference was minimal or not material.

Jeff, any further info would be of interest, here or in another article. Thanks.

Gary

Gary, we’ve just about exhausted my knowledge on the subject. David Hughes wrote a great (and extremely rare) book called A Bottle of Guinnesss. Try to find that. He dishes a lot of info (Hughes is an ex-Guinness brewer).

Thanks Jeff, I do know that book well. Unfortunately he deals with bottled Guinness only. The message there was, at its best, unfiltered bottled Guinness was rather superior to the filtered and pasteurized bottled beer but much more inconsistent, therefore, the latter version is best because consistently good. It is possible that the same is true of draught Guinness, but it would be good to have more detail, for both drinks in fact…

Anyway thanks and looking forward by the way to any reports to be delivered viz. that Carlsberg heritage lager.

Gary

Gary

Well, there’s the opening for Guinness to release a bottled “raw” version of it’s famous stout. mmmmmm

Cheers, Jeff! Great read, informative and it warms my heart that you met Mr Ash before he left us. I will share this story with all. Come have a Guinness on me one day in Las Vegas.

Best regards,

Wally

Excellent article about my favorite beer. I love knowing how that wonderful creaminess came about. I will lift my next Guinness to Mr Ash….and probably many more after that.

Cheers, Jade

Sadly this history is completely misleading about the origin of the very creamy draught Guinness. This was invented NOT by Michael Ash, although he did devise a special form of keg for the British market, but by the Dublin publicans. When Guinness introduced aluminium casks to replace the wooden barrels the Dublin publicans found that it was a lot easier to bring up the Guinness from the cellars if the casks were given a top pressure of air. Then they and their customers noticed that this gave a very creamy pint. Guinness investigated this and found that the oxygen in the air was best removed to preserve the flavour and life of the Guinness thus leaving nitrogen. This historical clarification comes from Tony Carey who started his 33 year brewing career with Guinness in 1963. A further twist to the story is that the design of Ash’s keg did not allow sufficient nitrogen to give the true creaminess of the Dublin draught. So Guinness in Ireland had to come up with a separate external high pressure gas cylinder to maintain the optimum level of dissolved nitrogen when dispensing from the cask or keg