The Craft of Making Beer Barrels

After a steady decline, are British coopers ready for a resurgence?

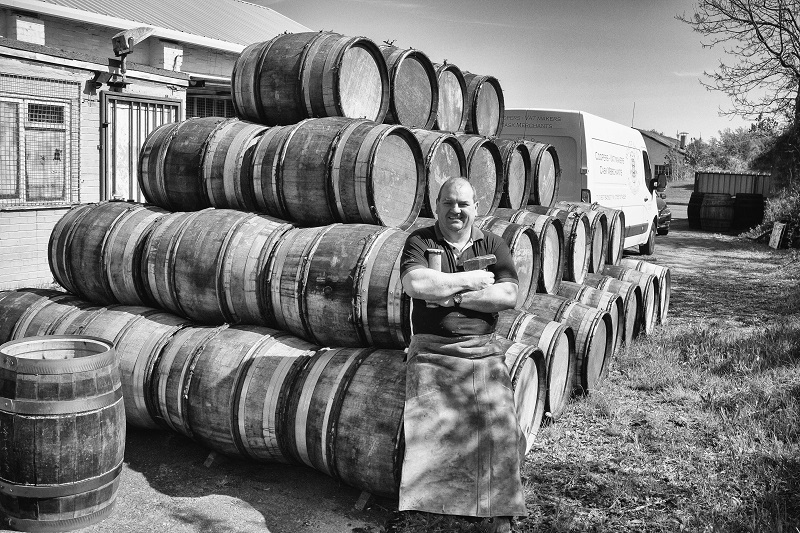

Alastair Simms of White Rose Cooperage. (Photo by Mark Wayt)

Alastair Simms, of the White Rose Cooperage, starts each day at 6 a.m. with a mug of Yorkshire tea. It’s a departure from his early days as a cooper. “We used to come in, lay our tools down at 5 o’clock and go across to the brewery and have a couple of pints,” says Simms, one of just a handful of coopers still working in the British beer industry. “And then we’d start work!”

Wooden barrels have been used for the storage of liquids and other materials for 2,000 years, and coopering was once a central and extensive role in a British brewery.

There was a steady decline through the 20th century as beers stopped being long-aged, transported and served in wood. This coincided with the increasing use of easy-to-maintain stainless steel, which made the job of a brewery cooper obsolete in all but a handful of traditional breweries, meaning this longtime brewing craft was barreling toward extinction.

Now, as brewers’ interest in wood barrels and tanks increases, is there hope for a resurgence in coopering for the beer industry?

A Dying Trade?

Britain’s most famous brewing town, Burton-upon-Trent was built on barrels of pale ale, and every drop of its famous beer passed through wood at least a couple of times. At its peak in the late 19th century, Bass—then the town’s and the world’s largest brewery—employed 400 coopers, who were responsible for half a million casks in circulation for draft beer and another half a million for fermenting, maturing and transporting beer. They were one of 30 breweries in the town at that point and thousands more around the country, all needing coopers. (The term barrel is used throughout this article. This is in the general sense of a barrel or cask of beer and not the official “beer barrel” volume unit, which is 117 liters, or 31 gallons.)

David Poulter is a cooper at Samuel Smith’s Brewery. (Photo courtesy Merchant du Vin)

Mark Newton is now the only cooper left in Burton-upon-Trent. He works at Marston’s Brewery and is one of just three coopers employed full-time by a British brewery—the others are Jonathan Manby at Theakston Brewery in Masham and David Poulter at Samuel Smith’s Brewery in Tadcaster. Newton’s cooperage is next to what Marston’s calls the “Cathedral of Brewing”: its Union Room. (Marston’s does have another trained cooper, but he doesn’t currently work in the cooperage).

The Burton Union System is made up of wooden casks lined side-by-side with a large tray above them. During fermentation, yeast and beer bubble out of the top of the barrel and up through swan neck pipes. They collect in the tray. The beer is returned to the barrels, and the yeast is drawn off for either the next brew or to go to the nearby Marmite factory. It started as an ingenious system to separate yeast and beer that also had the effect of good fermentations and clean pale ales—important at a time when beer glasses were becoming more common.

Newton’s task is to maintain the 300 barrels in the historic Union System, which involves removing three or four casks a week, checking them and making any repairs. “It’s a laborious, expensive process,” he says, “but it’s how they’ve always done it. The Unions haven’t changed at all.” It’s an integral part of Marston’s Pedigree, its traditional Burton pale ale.

Does Newton feel a weight of importance being the only cooper left in Burton? To answer, he shows me an old plane, a tool used for shaping wood. It was given to him by a retiring cooper who, in turn, had it given to him by his predecessor. It’s dark-brown wood, rubbed smooth and shiny like marble, with deep thumbprints in each side of the handle, pressed there from a century of constant use. “They told me it was a dying trade when I started in the late ’70s. ‘You’re daft’, they said. ‘Don’t you want to do something else?’ But I’ve never been out of work. I’ve enjoyed it. I’ve been working in the same trade for almost 40 years, and not many people can say that.” It’s an indirect answer, one by someone proud to be continuing the traditions, but also someone who doesn’t appear to be looking too far into the future or to the wider beer world.

Makers, Maintainers and Merchants of Barrels

Being aware of what’s happening around the beer world is not an issue 100 miles north of Burton in Wetherby, West Yorkshire, where Alastair Simms is flat-out busy supplying and building barrels for dozens of breweries out of his White Rose Cooperage.

Simms bought himself the cooperage as a 50th birthday present in May 2013. His career started 35 years earlier when he began his apprenticeship at Theakston Brewery, remaining for 16 years, before moving south to Wadworth Brewery. Today his White Rose Cooperage is a dusty jumble of different-sized casks, blackened old barrels, rusted metal hoops, wine-stained staves and decades-old tools. There’s nothing modern in sight.

The White Rose Cooperage is a maker, maintainer and merchant of barrels. It can build one complete new cask in a day or remake four casks in a day, which involves ‘knocking down’ a larger cask to put it back together as a smaller one; it can maintain, repair or repurpose old or broken barrels, including large cider vats; and it can source barrels from distilleries, do any necessary work, and send them on to breweries.

Working as an independent cooperage, Simms has the flexibility to take on whatever projects brewers have for him (and nonbrewers: He’s become the go-to cooper for Warner Bros., supplying barrels for a couple of Hollywood movies such as Ron Howard’s “In the Heart of the Sea.”). “I’m doing things now that I was told you shouldn’t do as a beer cooper,” he says, like working with whisky and wine barrels. “We used to make damned sure that no flavor imparted into the beer from the wood, but now that’s all part of the cask.”

As someone who’s been doing this traditional job all his working life, he’s now getting excited about new projects, particularly brewers being more specific about exactly what they want. “I’m getting these different requests every day, and I just say: ‘You tell me exactly what you want and why, and we’ll work out how to do it.’ ”

Simms is enjoying these new challenges. Recently he’s had brewers talking to him about making a small Burton Union System, wooden cooling trays, bespoke barrels with various different woods and chars, oak foudres, even new oak mash tuns and conical wooden fermenters. “I’d love to see a resurgence in large aging vats, like we used to have for porter,” he says. “That’s what I really want to build.”

Coaxing Character

“Nothing is more important to us than wooden barrels,” says (the aptly named) Andrew Cooper, co-founder of Wild Beer Co. “Everything we do is worked around wood—they are the reason we started the brewery.” Wild Beer Co. currently has 400 barrels, a number limited by the space in its farm buildings in Somerset.

“We love the characteristics of barrel-aged beers. The complexity, the way the beer slowly oxidizes and evolves, the layers of flavor you can get through blending,” plus how wood can “give yeast and bacteria the perfect environment to do their thing.”

Wild Beer Co. has worked with White Rose to have a very heavy char on some barrels: “We are re-charring them for a specific flavor in a specific beer,” says Cooper, looking to get a fiery, smoky quality. This specificity is another new aspect of coopering and brewing; the brewery can manipulate wood to give unique qualities, and it’s an extension to choosing different hops, grains or yeast strains.

Expansion plans at Wild Beer Co. will see the number of barrels significantly increase. Will it also mean looking into different wooden vessels like mash tuns, fermenters, foudres or even brewing kits? “We want to specialize in fermentation and aging techniques, and we want to try all different things that can give us great beer,” Cooper says. “There are many possibilities.”

At The Junction, all cask beers are served in wooden barrels. (Photo by Daniel Bradford)

It’s not just breweries that are looking at wooden barrels. A fine example of wood reaching the drinker is The Junction, a pub in the industrial ex-mining town of Castleford. Here, every cask beer is served from wooden barrels. It’s probably the only pub in the world to do this. “Everyone told us it couldn’t be done,” says Neil Midgley, the pub’s landlord. He’s proved them wrong.

“Sometimes you’ve got to go backwards to move forwards,” he says. “Every pub used to serve all their beer from wooden barrels, and any pub can still do it today.” Since 2010 he’s bought 180 wooden barrels (mostly from Simms). Some are ex-wine or whisky, including some that are 80-100 years old; there are various woods and sizes. He’s also commissioned a couple of virgin oak barrels to be built. Midgley sends the barrels to breweries to fill up and return to him; he treats the beer like a regular cask ale, so he’s not maturing the beers. He’s just using the barrels to serve.

It’s been 30 years since British drinkers got to routinely drink ales from wooden barrels. For Midgley it’s a return to that which is important. He’s also found that the beers take on new qualities, noticeably being more mellow, soft and more expansive compared to steel cask beers. “I’ve had brewers come in here and say, ‘My beer is better here than anywhere else.’”

Promising Future

When it comes to wood in breweries, we’re becoming blasé about barrels. We see them stacked up; we see photos of barrel warehouses, lines of foudres; we drink barrel-aged this and that. And it’s made barrels seem exciting again even though they’ve been a part of brewing for centuries. We’ve almost forgotten the barrel itself in our focus on the liquid inside, meaning we’ve overlooked that all of those wooden barrels were built by coopers. They didn’t just arrive off the back of a truck like mass-manufactured steel kegs. So in spite of the industry changes, these few British coopers have kept going. And now the industry is changing again.

The White Rose Cooperage has seen significant growth in business, and to keep up with orders, Cassandra Phillips, an Aussie wine cooper, was hired. Soon after, Simms advertised for an apprentice, with Kean Hiscock, a 19-year-old local lad, getting the four-year on-the-job training.

With busted knuckles and the boulder shoulders of a rugby league player, Hiscock now spends his day with a five-pound hammer in his hand and is doing the training that every cooper before him has had to do—there are no amateur coopers, and every one has been apprenticed in this same way. “I do feel an importance coming into this,” he says. “Coopering is a rare job and I just want to learn and do my best.”

Theakston and Samuel Smith also both have an apprentice, and Simms is considering taking on a second. That makes five full-time beer coopers and three apprentices. From a craft that was threatening to die and disappear, there are hopeful signs for its survival.

The role of a beer cooper is changing in Britain and beyond. It’s still physical, it still involves building beer barrels, but there are new challenges and new demands. More importantly, there are new opportunities, whether that’s bringing back porter butts, building oak fermenters or juggling dozens of used spirit barrels and sending them on to breweries and pubs around the world.

“There’s lots of potential for the future, and we could get to the point where a new brewery employs a cooper,” says Simms. “I just don’t know where he’d come from.” He pauses and looks up: “Actually, I do know where he comes from,” and he nods to his apprentice.

Until then, it’s Hiscock’s job to work hard, learn fast, and make the tea by 6 a.m.

The following beers were tasted by Ken Weaver, the beer editor at All About Beer Magazine.

Avery Expletus & Lunctis Viribus

ABV: 5.9% + 5.4% | Barrel-Aged Sour AleTasting Notes: Barrels Used: Tequila + Tequila & Cabernet Sauvignon Both of these are excellent—let’s get that out of the way early. The Expletus leads with bright red berries and a color like peach juice, where Lunctis brings deep, copper-tinged ruby. Both offer up mouthwatering acidity, a wide terrain of red fruits (the Lunctis heading darker, to notes of black cherry and plum) and just a hint if any tequila-barrel tang.

Sudwerk Fünke Hop Farm

ABV: 6.5% | Dry-Hopped Sour SaisonTasting Notes: Barrels Used: Grenache & Petite Sirah Multiple batches of this have been beautiful. Sudwerk makes this via a blend of barrel-aged beers, sourcing its Petite Sirah and Grenache wine barrels locally. Bright, sweet-lemon tartness leads throughout this beer, but the barrel contributions of ripened cherry, strawberry and well-toasted oak offer a lot of complexity underneath. Its wine-like elements, edged with tannins, are welcome, pairing deep red fruit to ideal bubbles and acidity.

Mark Dredge

Mark Dredge is a beer and food writer from London. Follow him on Twitter @MarkDredge

Thanks for the good read. I do hope to see more Coopers employed, but i may be biased – my wife and i came up with our son’s middle name while on a visit to Theakstons many years ago. I voted for Peculiar but Cooper was probably the better choice.